![]()

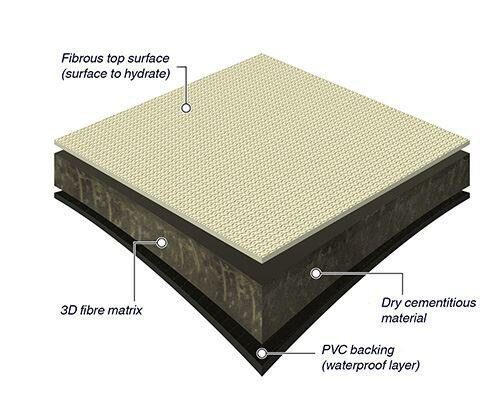

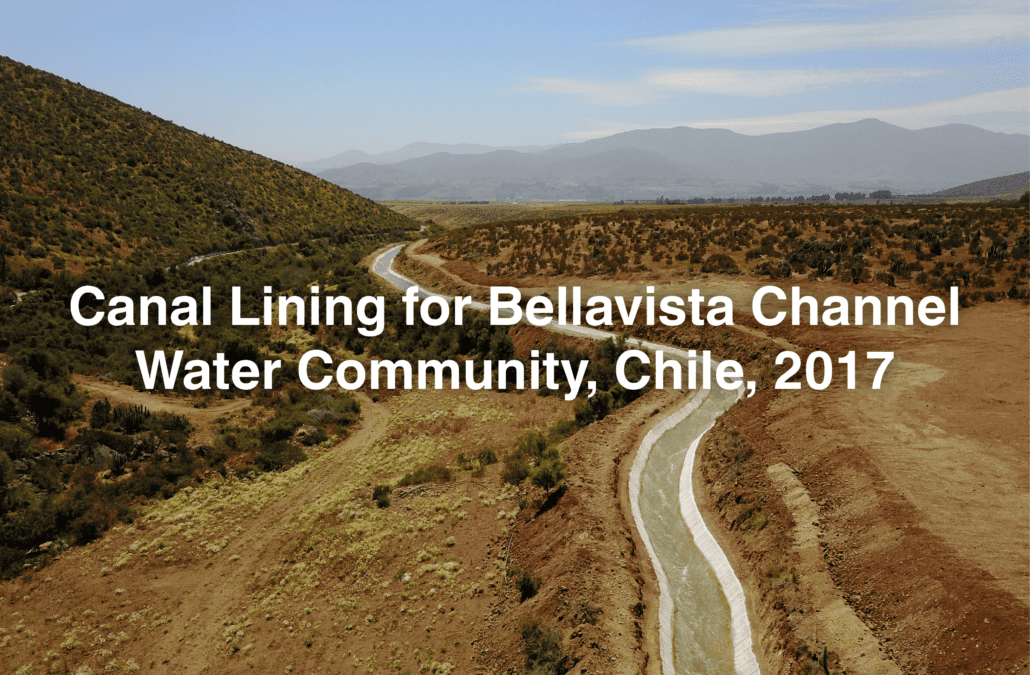

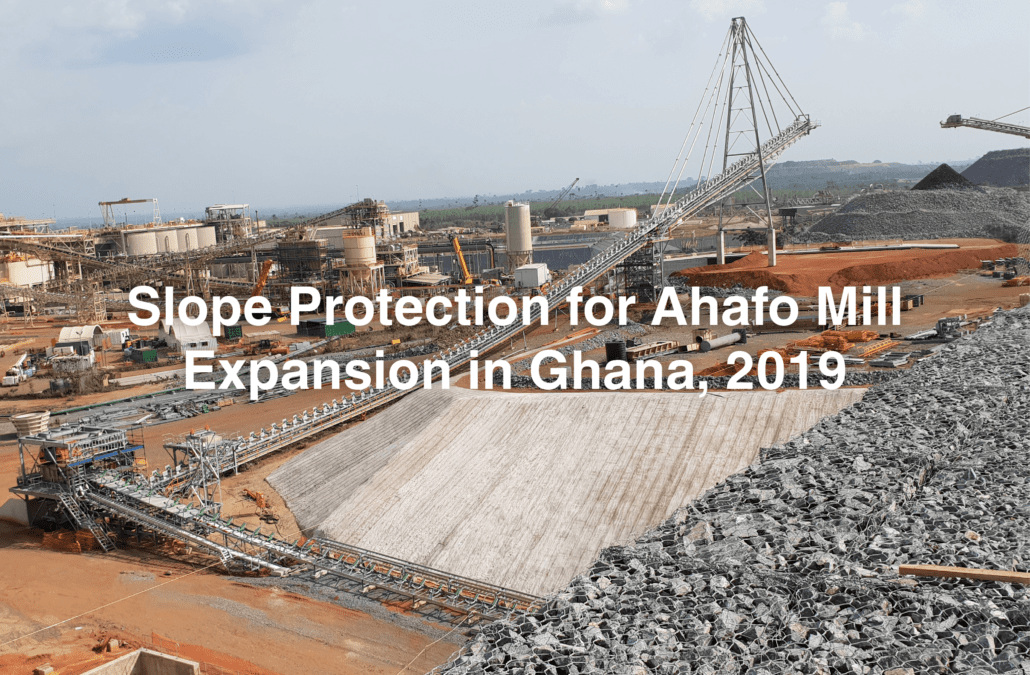

Concrete Canvas® is used for a wide range of erosion control and weed suppression applications. It allows concrete construction with minimal plant and specialist training.

Typically ten-times faster to install than conventional solutions, essentially its Concrete on a Roll™: simply unroll and Just Add Water.