Technical Note 1: Specifying GCCMs with ASTM D8364

Introduction

This series of Technical Notes consider the importance of using GCCM (Geosynthetic Cementitious Composite Mat) specific ASTM standards when selecting GCCM materials for use on erosion control projects:

The Problem:

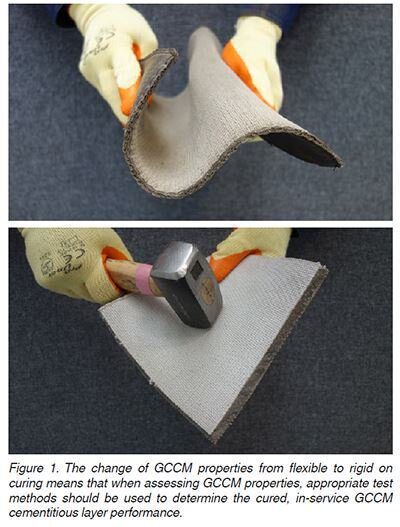

GCCMs are unlike most geosynthetics as their properties change on hydration from flexible to rigid. Both the uncured (pre-set, soft and flexible) and cured (post-set, hardened and rigid) properties need to be reported to understand the GCCM capabilities in both deployment and in-service respectively.

GCCMs contain geosynthetic and cementitious materials, both of which possess very different physical properties. Geosynthetics are typically buried and their performance is often assessed according to their tensile strength, whereas hardened cementitious materials are often exposed and their performance is typically assessed according to their compressive strength, which is typically correlated with other key characteristics such as abrasion resistance, freeze thaw resistance and resistance to chemical attack.

GCCMs are the only geosynthetic to contain unset cementitious material and pre-existing geosynthetic test standards do not include methods for understanding the performance of the cementitious material contained within a GCCM. It is therefore important to test the properties of the cured cementitious material so that the behaviour of the GCCM as a hardened composite can be understood. It is also critical to ensure the cementitious material is cured at a water/powder ratio that is representative of field (in-service) hydration and not artificially controlled in the laboratory.

The Solution:

Since 2015, the ASTM International Standards Organisation and its D35 Geosynthetics Committee has published a number of standards specifically for GCCMs to address the shortfalls in using pre-existing geosynthetic or concrete standards. These GCCM specific standards enable consistent, accurate reporting of essential GCCM properties.

They include:

- ASTM D8364 ‘Standard Specification for GCCM materials’

- ASTM D8329 ‘Standard Test Method for Determination of Water/Cementitious Materials Ratio for GCCMs and Measurement of the Compressive Strength of the Cementitious Material Contained Within’

- ASTM D8058 ‘Standard Test Method for Determining the Flexural Strength of a GCCM Using the Three-Point Bending Test’

- ASTM D8030 ‘Standard Practice for Sample Preparation for GCCM’

These standards have been created to ensure that repeatable testing and reporting of GCCM properties is conducted on specimens that have been prepared in a manner that is consistent with their use in the field, so the test results are representative of GCCMs installed in real-world operating conditions. Applying non-GCCM tests can result in properties that vary by an order of magnitude from field properties.

This Technical Note 1 focusses on the importance of using ASTM D8364 for specifying GCCMs.

ASTM D8364 GCCM Product Standard:

In March 2021, ASTM International published ASTM D8364/D8364M-21: ‘Standard Specification for Geosynthetic Cementitious Composite Mat (GCCM) Materials’.

ASTM D8364 is the only internationally recognised standard for specifying GCCMs and lists typical GCCM erosion control and weed suppression applications by three Classification Types: Type I, Type II and Type III.

Type I GCCMs:

- Have minimal requirements for abrasion and wear

- Are for low shear stress and flow velocity applications

- Are not subject to impact loads

- Must be Installed over a dense subgrade

Typical Type I GCCM applications include:

- Slope protection

- Weed suppression

- Berm protection

- Remediation of concrete hydraulic structures

Type II GCCMs:

- Have greater requirements for abrasion and wear

- For shear stresses >50kg/m2 and flow velocities >6m/s

- Subject to impact loads

- Installed over medium dense subgrades

Typical Type II GCCM applications include:

- Channel Lining

- Culvert Lining

- Slope protection

- Remediation of concrete hydraulic structures

Type III GCCMs:

- Are used where additional flexural strength is required due to loose subgrades

- Are expected to be more durable and longer lasting than lower grade types in the same application

Typical Type III GCCM applications include:

- Channel Lining

- Armouring

- Culvert Lining

- Slope Protection

ASTM D8364 details the minimum performance properties of the GCCM Types, based on GCCM specific test standards and methodologies that represent the required in field performance of a GCCM product when used in typical erosion control applications.

It is important that users only consider GCCM manufacturers performance property data that complies with the GCCM specific test standards listed in ASTM D8364, so that the information is representative of field performance. ASTM D8364 specifies that the GCCM specimens must be prepared in accordance with ASTM D8030 prior to performance testing so that the reported properties are representative of the worst-case hydration by immersion.